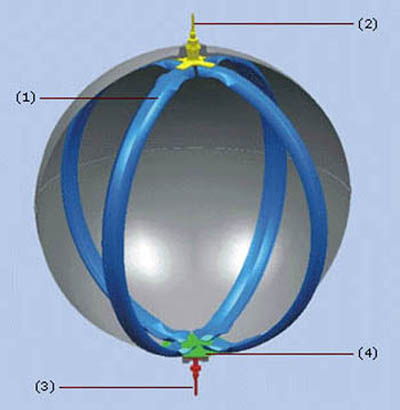

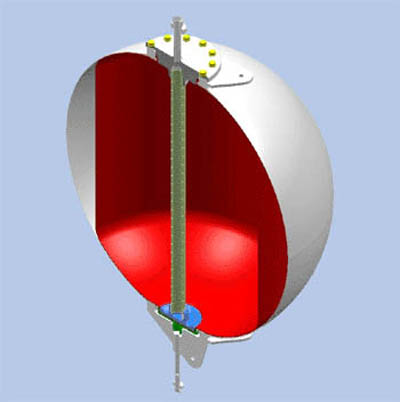

Hydrazine Bladder Tank

Hydrazine Bladder Tank

A bladder tank comprises a rigid vessel containing a flexible bladder and perforated axial stand-pipe. Propellant is contained in the bladder and pressurant gas within the tank occupies the volume between the tank wall and bladder. The pressurant gas 'squeezes' the bladder forcing propellant through the stand-pipe to achieve a positive expulsion of propellant to a rocket engine or a set of thrusters.

Operational Modes

The bladder tank may be operated in either blow-down mode, or pressure regulated mode. In blow-down mode, the tank is loaded with propellant and 'locked-up with a specified gas mass. This mode avoids the need for additional gas pressurant vessels thereby reducing mass, volume and propulsion systems complexity. The fixed gas mass does however result in diminishing pressure during operation resulting in reducing thrust from Beginning of mission Life (BOL) to the End of Life (EOL). The reducing thrust level can however be very accurately predicted with guaranteed repeatability.

In pressure regulated mode, the tank is pressurised from an independent pressurant vessel, via a pressure regulator, supplying a constant pressure from BOL to EOL. Consequently the propellant supply pressure, hence thrust, is constant throughout operational life.

Advantages

Whether operated in blow-down, or pressure regulated mode, the bladder tank advantages include:

- Functional simplicity => reliability.

- Minimum propellant residuals.

- Elimination of gas/propellant mixing assuring predictable thrust conditions, especially during reignition.

- Guaranteed propellant availability throughout all mission phases, irrespective of accelerations, coast phase decelerations, manoeuvring, start-up and shut-down conditions.

Typical Applications

Our bladder tanks are used on the 400 N Attitude and Orbital Control System (AOCS) of all versions of Ariane 5 and in the VEGA 200 N Roll and Attitude Control System (RACS). In these application, the control systems are designed and operated in blow-down mode.

The 400 N hydrazine AOCS is located in the Vehicle Equipment Bay, which forms a part of the Ariane 5 upper stage.

The 400 N AOCS is both versatile and multifunctional enabling roll and pitch control of Ariane 5 during its ascent as well as all upper stage manoeuvres preparatory to the separation of one or more payloads. The 400 N AOCS can easily be adapted by varying the numbers of bladder tanks according to mission demands. The bladder tank is also used on ESA's Atmospheric Re-entry Demonstrator.